History

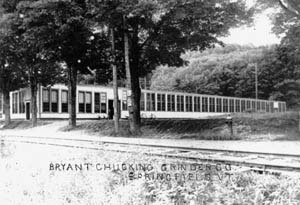

Bryant Chucking Grinder (more

commonly known as "Bryant Grinder") was founded on March

29, 1909 by William LeRoy Bryant.

William Bryant was an Engineer

at the Jones & Lamson Company during the early 1900's when

he developed the first grinding machine. It was a chucker

model with 3 independent controlled grinding wheels, one

for the OD, one for the ID and one for face grinding, thus,

allowing all surfaces to be ground in one chucking. James

Hartness, President of Jones & Lamson, helped finance the

start up and became the first President of Bryant Grinder.

By 1910, a 20,000 sq ft building was built on the current

location across the street from J&L. During the same year,

9 machines were shipped to Ford and Cadillac. By 1912, a

single spindle hole grinder was developed, along with two

other models and sales doubled. This provided the first

annual profit of $59.00.

By 1910, a 20,000 sq ft building was built on the current

location across the street from J&L. During the same year,

9 machines were shipped to Ford and Cadillac. By 1912, a

single spindle hole grinder was developed, along with two

other models and sales doubled. This provided the first

annual profit of $59.00.

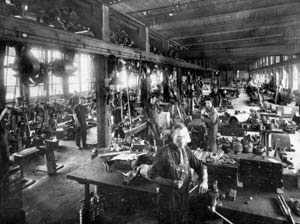

With the outbreak of World

War I the plant doubled in size, by 1917 running 3 shifts

a day. Additional space was rented from J&L to help produce

artillery shells. The war promotion created two new machine

models especially for the aircraft industry. In fact, Bryant

earned such a reputation for accuracy and precision, virtually

90% of the grinding done on aircraft engines was performed

on Bryant machines up to the advent of the jet engine. During

WWI Ford Aircraft Division had 102 Bryant machines busy

producing the famous Liberty engine.

Firmly established in the automotive

and aircraft sectors, Bryant began producing machines for

the bearing industry. By the end of the twenties, sales

averaged 142 machines per year. The Great Depression arrived,

causing most companies to close. With the start of its first

5-year plan, the Soviet Union became the savior of Bryant

Grinder with annual sales of up to 30% coming from the USSR.

In 1931, William LeRoy Bryant

died. Bryant was replaced by E.J. Fullam, than Treasurer

of the Fellows Company.

With the downturn of the 30's,

improvements were made to the machine designs. Some machines

were made into semiautomatic, hydraulics replaced air and

automatic sizing became available as an option. During this

time motorized spindles became a reality.

With WWII on the horizon, business was building rapidly.

By 1938, sales had tripled and by 1940, the US Ordnance

Department requested that Bryant expand the building to

127,000 square feet. By 1942, the workforce grew to 1350

people with 200 of them being women. Production peaked at

3.5 machines per day. Demand was so high that 750 machines

had to be built outside by the Draper Corporation, Hopedale,

MA over a two-year period.

With WWII on the horizon, business was building rapidly.

By 1938, sales had tripled and by 1940, the US Ordnance

Department requested that Bryant expand the building to

127,000 square feet. By 1942, the workforce grew to 1350

people with 200 of them being women. Production peaked at

3.5 machines per day. Demand was so high that 750 machines

had to be built outside by the Draper Corporation, Hopedale,

MA over a two-year period.

Bryant was awarded the Army-Navy

E Award in August 1942. With all of the war production in

the "Precision Valley", Springfield, VT ranked No. 7 most

important bombing target in the country.

As the war raged in Europe,

machine production dropped off and Bryant began building

radar units for Raytheon and General Electric. In addition,

Bryant participated in the workings of the highly secretive

Manhattan Atomic Bomb Project. Bryant also worked with Bendix

on grinding bores to .000005" for use on fuel pumps for

the B-29 bombers. This program lead to the development of

the Bryant 1309-W model, designed especially for fuel injection

nozzle production. The first 1309-W was shipped to France

in 1949, followed by 4 domestic shipments and 11 to Japan,

Australia and other European countries. A Bryant grinder

was the first American machine tool to enter Japan after

the war.

In 1946, Joseph B. Johnson,

a long time employee who later became Governor of Vermont,

became Vice President and General Manager. Business was

again slow in the late 40's. But with the Korean War in

the winds, business increased sharply in 1950. This time,

production required two outside builders, Dexter Folder

of Pearl River, NY joined Draper to keep pace with demand.

In keeping with production, the 9" series of machines were

introduced along with the very popular "Centalign C". The

Centalign design was innovative having both traverse motions

of the wheel on one slide and on the same plane as the work

centerline. Demand was so great that Bryant started a subsidiary

in England in 1956. In addition, Bryant purchased the E.G.

Staude Division of Sperry, a manufacturer of printing presses

and packaging machinery.

In the middle 1950's, with

its expertise in spindles, Bryant designed a computer memory

drum, which eventually became a separate division. In 1958,

Ex-Cell-O Corporation of Detroit, MI purchased Bryant by

an exchange of stock. Business again surged and Bryant found

themselves shipping 30% of its product outside the United

States. The Computer Products Division grew very rapidly

and was eventually moved to Walled Lake, MI and rolled into

another Ex-Cell-O division.

Bryant received a very large

order from the Soviet Union for Centalign B grinders in

1960. A year later, after a lot of work was done, the US

Commerce Department revoked the export license. Bryant had

always been known as a leader in machinery export. By 1963,

Bryant was awarded the President's "E" Award for Exports.

The Bryant Centa-Form OD grinding

machine was introduced in 1964, solidifying Bryant's position

in the external grinding market. Business progressed through

the 60's without major interruptions. A mild decline in

business in 1967 lead to a recession in 1971, substantially

reducing the workforce. Bryant acquired the precision external

centerless grinder line from Van Norman in 1972, which further

diversified the Bryant line and contributed to overall sales.

During the 1970's, Bryant continued

to develop technology by introducing 6 new models. But none

compared to the Bryant Lectraline LL3 machine produced in

1979. The LL3 was the first CNC multi-surface grinding machine

in the world. It was later introduced and demonstrated at

the International Manufacturing Technology Show in 1980.

The LL1, LL2 and LL4 size machines were soon to follow,

giving Bryant the capacity of grinding internal diameters

from .040" ID's to 88" OD's.

In the summer of 1986, Ex-Cell-O

and its subsidiaries, including Bryant, were purchased by

Textron, Inc.

In May of 1988, Textron Inc.

sold Bryant Grinder to a financial investment group with

limited experience in the machine tool industry which resulted

in some difficult times for the company, it's customers

and suppliers. During February of 2002, Bryant Grinder suddenly

closed it's doors to business, prompting many to speculate

that the company would never do business again.

On July 18, 2002 Vermont Machine

Tool, founded in 1983 by Craig B. Barrett, purchased the

inventory, work-in-process and all intellectual properties

of Bryant Grinder. Mr. Barrett, formerly with Jones and

Lampson, brought a vision and drive for excellence to the

acquisition as exemplified by seeking out the best qualified

Bryant employees and hiring them to form the core of the

new Bryant Grinder staff. Together with the experienced

crew of Vermont Machine Tool, the new Bryant Grinder team

forms a nucleus of forward looking, motivated and innovative

people intent upon sharing new, creative successes with

their customers.

As corporate America is changing

so is Bryant Grinder under the guidance of Vermont Machine

Tool. Work forces have become smaller as businesses become

leaner. The machine tool industry has changed as foreign

competition has become stronger. Many companies have been

unable to survive.

Bryant Grinder has managed by

producing OD grinders and expanding the CNC versions of

the Lectraform LF2. This model quickly became one of the

best sellers in the modern history of Bryant Grinder. Now

with a full line of Internal and External precision CNC

grinding machines, Bryant intends to maintain its position

in the world as a leading manufacturer of application driven

machine tools.